SPOTO ASQ Certification Dumps List

-

CATEGORIESEXAM TRACKSEXAM QUESTION NUMBERDUMP COVERAGEPass Exam DUMPSFREE TEST

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

ASQ500+100% cover

-

Luc***2026/03/07order Other ***Hen***2026/03/07order Other ***Ale***2026/03/07order Other ***

-

Mas***2026/03/07order Other ***Mic***2026/03/07order Other ***Eth***2026/03/07order Other ***

-

Dan***2026/03/07order Other ***Jac***2026/03/07order Other ***Log***2026/03/07order Other ***

-

Jac***2026/03/07order Other ***Lev***2026/03/07order Other ***Seb***2026/03/07order Other ***

-

Mat***2026/03/07order Other ***Jac***2026/03/07order Other ***Owe***2026/03/07order Other ***

-

The***2026/03/07order Other ***Aid***2026/03/07order Other ***Sam***2026/03/07order Other ***

-

Lia***2026/03/07order Other ***Noa***2026/03/07order Other ***Oli***2026/03/07order Other ***

-

Eli***2026/03/07order Other ***Wil***2026/03/07order Other ***Jam***2026/03/07order Other ***

-

Luc***2026/03/07order Other ***

-

Mas***2026/03/07order Other ***

-

Dan***2026/03/07order Other ***

-

Jac***2026/03/07order Other ***

-

Owe***2026/03/07order Other ***

-

The***2026/03/07order Other ***

-

Lia***2026/03/07order Other ***

-

Wil***2026/03/07order Other ***

ASQ Certified Quality Technician (CQT) Exam Overview

A Certified Quality Technician (CQT) plays a vital role in supporting quality assurance and control by conducting inspections, gathering measurement data, and analyzing results to ensure products meet defined standards. This ASQ certification validates your ability to apply foundational quality concepts, statistical techniques, calibration methods, inspection and testing procedures, audit practices, and risk-mitigation strategies in real-world settings.

.jpg)

Certified Quality Technician Certification

ASQ CQT

110 multiple-choice questions

4.5 hours

$447

English

Exam Format:

Open-book; computer-based or paper-basedA Certified Quality Technician (CQT) plays a vital role in supporting quality assurance and control by conducting inspections, gathering measurement data, and analyzing results to ensure products meet defined standards. This ASQ certification validates your ability to apply foundational quality concepts, statistical techniques, calibration methods, inspection and testing procedures, audit practices, and risk-mitigation strategies in real-world settings.

.jpg)

Certified Quality Technician Certification

ASQ CQT

110 multiple-choice questions

4.5 hours

$447

English

Exam Format:

Open-book; computer-based or paper-basedExam Topics & SPOTO Question Bank

1.ASQ CQT Exam Body of Knowledge

-

Quality Concepts & Tools (19 Questions)

-

Quality Concepts: Understand customer/supplier needs, product/process quality principles, standards/specifications, and cost-of-quality categories (prevention, appraisal, internal/external failure).

-

Quality Tools: Select, build, and interpret the seven basic quality tools (cause-and-effect diagrams, flowcharts, check sheets, Pareto charts, scatter plots, control charts, histograms), plus problem-solving techniques (5 Whys, 8D), Lean basics (5S, value-stream mapping), and continuous-improvement methods (PDCA, DMAIC, brainstorming, benchmarking).

-

Ethics: Apply the ASQ Code of Ethics in professional conduct.

-

-

Statistical Techniques (17 Questions)

-

Concepts & Terminology: Population vs. sample, parameters vs. statistics, normal distribution, SPC basics.

-

Calculations: Compute and interpret mean/median/mode, range/variance/standard deviation, and confidence intervals.

-

Control Charts: Differentiate control vs. spec limits; construct/analyze X̅-R, I-MR, p/np/c/u charts; calculate process-capability indices (Cp, Cpk, Pp, Ppk); interpret common vs. special causes.

-

-

Metrology & Calibration (16 Questions)

-

Measurement Equipment: Identify types of gauges, hand tools, optical and electronic devices, CMMs, surface-plate methods, profilometers, force-measurement tools.

-

Control & Maintenance: Establish identification, control, maintenance, and traceability of M&TE; validate customer-supplied equipment.

-

Calibration: Set intervals based on risk/usage; interpret calibration results, errors, and hierarchy of standards (reference → primary → transfer).

-

-

Inspection & Test (21 Questions)

-

Drawings & GD&T: Read engineering drawings, apply ASME Y14.5 geometric tolerancing, classify defect severity.

-

Inspection Concepts: Choose measurement types/instruments; perform MSA (gauge R&R); apply rounding rules and unit conversions; determine inspection points; manage traceability, CoC/CoA.

-

Sampling: Understand sampling plans (AQL, single/double/skip-lot, AOQ); select sample size and accept/reject criteria.

-

Nonconforming Material: Identify, segregate, document, and disposition nonconforming items; understand MRB processes.

-

-

Quality Audits (13 Questions)

-

Audit Types & Terminology: Internal/external, system/product/process audits; first-, second-, third-party distinctions.

-

Audit Process: Plan and scope audits, prepare checklists, conduct opening/closing meetings, classify findings, report and verify corrective actions.

-

Audit Tools: Use working papers, evidence gathering, trace-forward/trace-back, and audit sampling techniques.

-

-

Risk Management (14 Questions)

-

Assessment & Mitigation: Apply FMEA (PFMEA/DFMEA), fault-tree analysis, SPC trend analysis, and control plans; leverage customer complaints and warranty data.

-

Corrective Action: Follow problem-containment, root-cause analysis, solution implementation, and effectiveness validation.

-

Preventive Action: Identify potential failures, develop mistake-proofing, revise procedures, and verify preventive measures.

-

2.What Is the ASQ CQT Exam Dumps?

SPOTO's ASQ CQT dumps are meticulously assembled from live exam experiences and curated by certified quality technicians. Our bank faithfully mirrors the scope and difficulty of the official 110-question exam, giving you hands-on exposure to every major topic area before test day.

3.About SPOTO's CQT Question Bank

Each question in our repository is carefully mapped to the official Body of Knowledge and rigorously reviewed by experienced quality-control professionals. You'll gain:

-

Comprehensive Scope: Over twice the number of questions found on the live exam, covering all six domains in depth.

-

Real-World Scenarios: Practical case studies and inspection checklists based on manufacturing and service-industry examples.

-

Step-by-Step Explanations: Detailed solution paths, statistical calculations, and reference to industry standards.

-

Flexible Study Options: Choose from full-length mock exams, domain-specific drills, and live tutor-led workshops.

-

Rapid Content Updates: Our materials refresh within days of any ASQ syllabus change or new quality-control guidelines.

Achieve complete mastery in each domain within a focused 7-10-day study plan and approach your CQT exam fully prepared.

Latest Passing Reports from SPOTO Candidates

RELATED Practice test

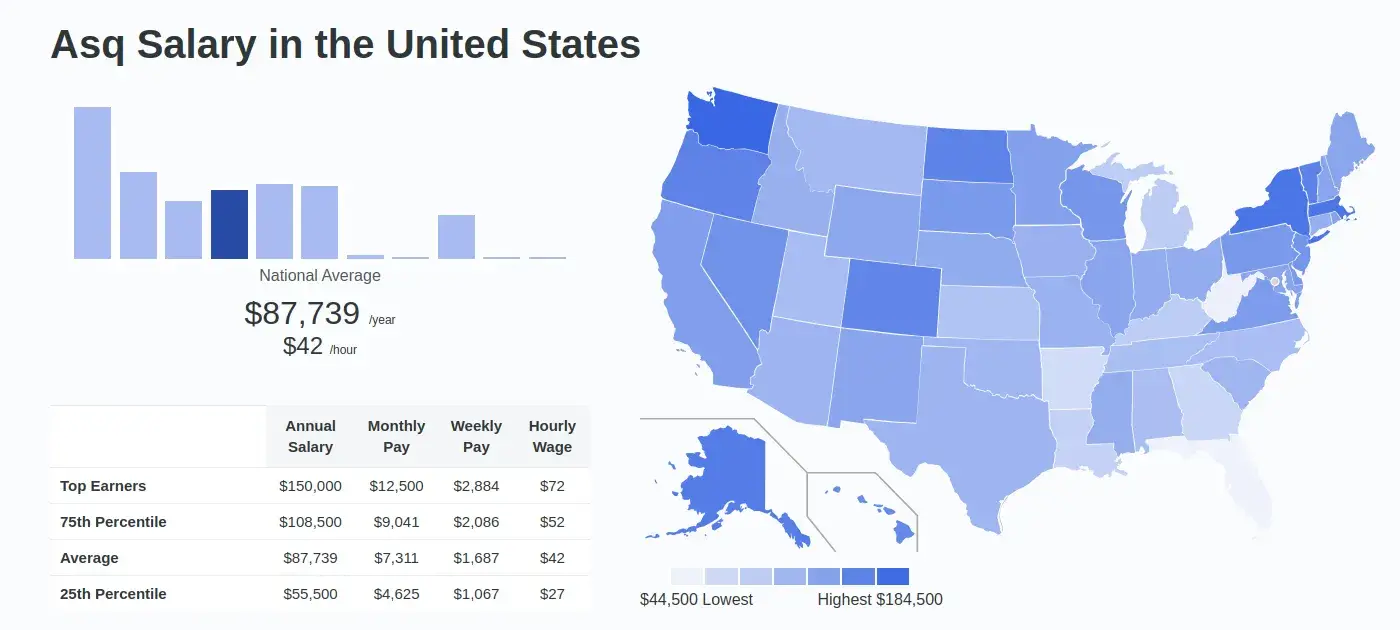

How Much Can You Make with the Certification?

Certified professionals can earn up to 40-percent more than their non-certified peers.

Certified Quality Technician (CQT) Exam Dumps FAQs

1.Do you offer discounts on CQT dumps?

Yes reach out to our sales team for current promotions, bundle packages, and seasonal deals when purchasing multiple ASQ certifications.

2.How do I access CQT exam questions after purchase?

Within 30 minutes of payment, you'll receive an email with your SPOTO account credentials and a quick-start guide. Log in to our mock-exam portal to begin practicing immediately.

3.What is SPOTO's pass rate for CQT dumps?

We maintain a proven pass rate exceeding 95%, backed by thousands of success stories shared in professional quality-assurance communities.

4.How long does access to CQT materials last?

Your standard access period is 7-10 days post-purchase. Need more time? We provide hassle-free renewals so you can extend your study window without losing progress.

5.How many questions are in the CQT dumps?

For comprehensive preparation, our bank contains roughly 2-3× the official 110 questions ensuring you master every tool, technique, and scenario you'll face on exam day.